SWSERIES

Nozzle Traverse Inner Rotor Coil Winder

SW-36-3N/

SW-36-2N

SW-36-3N and SW-36-2N wind coils directly onto the stator by variable number (from 1 to 6) of nozzles simultaneously. The original traverse device (patent pending) makes the three nozzles traverse simultaneously to wind the coils with high space factor.SW-36-3N is suitable for the production of DCBL fan motors with thick wire.SW-36-2N is recommended for the production of compressor motors with higher stacks.

■Specifications

- Winding speed

- 800rpm

- Number of nozzles

- 1,2,3,4,6

- Nozzle stroke

- 100mm[160mm]

- Winding direction

- reversible

- Wire size

- φ0.3-φ1.6mm

- Number of slots

- 6 or more

- Adaptive core bore

- φ30-φ120mm

- Adaptive core diameter

- φ60-φ160mm

- Adaptive core stack height

- 20-50mm[30-90mm]

- Dimensions

- 1080W×1400L×2200H

- [1080W×1400L×2500H]

- Weight

- 1500kg[1810kg]

- ※Figures for SW-36-2N indicated in[ ].

- ※Winding speed depends on the specification.

- ※Adaptive stack height of core depends on the insulator.

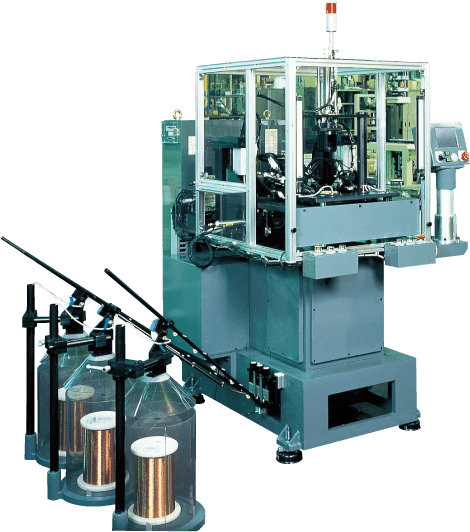

High-Speed Inner Rotor Coil Winder (Shroud Traverse Type)

SW-36-3/SW-36-2

SW-36-3 and SW-36-2 wind coils directly onto the stator by variable number (from 1 to 6)of nozzles simultaneously at high speed. The shroud traverses to achieve layer winding.SW-36-3 is suitable for the production of thin DCBL fan motors.

■Specifications

- Winding speed

- 2000rpm(Max)

- [1600rpm(Max)]

- Number of nozzles

- 1,2,3,4,6

- Nozzle stroke

- 30-100mm

- [30-130mm]

- Winding direction

- reversible

- Wire size

- φ0.1-φ0.7mm

- Number of slots

- 4 or more

- Adaptive core bore

- φ18-φ60mm

- Adaptive core diameter

- φ40-φ100mm

- Adaptive core stack height

- 5-40mm[5-70mm]

- Dimensions

- 1080W×1400L×1690H

- [1080W×1400L×1750H]

- Weight

- 1500kg[1800kg]

- Figures for SW-36-2 indicated in[ ].

- ※Winding speed depends on the specification.

- ※Adaptive stack height of core depends on the insulator.

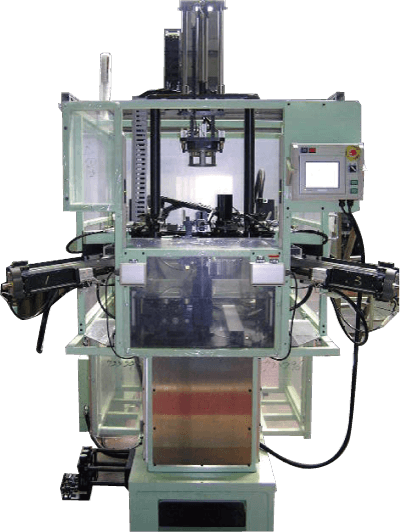

Nozzle Type Outer Rotor Coil Winder

SW-35-4

SW-35-4 wind the U,V and W coils directly onto the stator from three nozzles.SW-35-2 shuttles the core and SW-35-4 does the nozzle vertically for coil-winding. A traverse device on the three nozzles aligns the coils. These machines are suitable for the production of outer rotor motors with many slots.

■ Specifications

- Winding speed

- 300rpm

- Number of nozzles

- 1,2,3

- Nozzle stroke

- 30-80mm

- Winding direction

- reversible

- Wire size

- φ0.4-φ1.0mm

- Number of slots

- 24 or more

- Adaptive core bore

- φ50-φ170mm

- Adaptive core diameter

- φ160-φ280mm

- Adaptive core stack height

- 15-40mm

- Dimensions

- 1000W×1900L×1700H

- Weight

- 1200kg

- ※Winding speed depends on the specification.

- ※Adaptive stack height of core depends on the insulator.

Nozzle Traverse Inner Rotor Coil Winder

SW-36-2N(large type)

SW-36-2N have the case for a lead line. This case helps the line no disconnection and no scratching SW-36-2N is recommended for the production having a long lead line, and many nozzles.

■Specifications

- Winding speed

- 800rpm(Max)

- Number of nozzles

- 3

- Nozzle stroke

- 160mm

- Winding direction

- reversible

- Wire size

- φ0.3-φ1.6mm

- Number of slots

- 9 slots(nozzle arragement 40°)

- 12 slots(nozzle arragement 30°)

- Lead line length

- 400-600mm

- Number of a lead line

- 24(Max)

- Adaptive core bore

- φ30-φ120mm

- Adaptive core diameter

- φ60-φ160mm

- Adaptive core stack height

- 30-90mm

- Dimensions

- 2300W×1600L×3000H

- Weight

- 2200kg

- ※Winding speed depends on the specification.

- ※Adaptive stack height of core depends on the insulator.

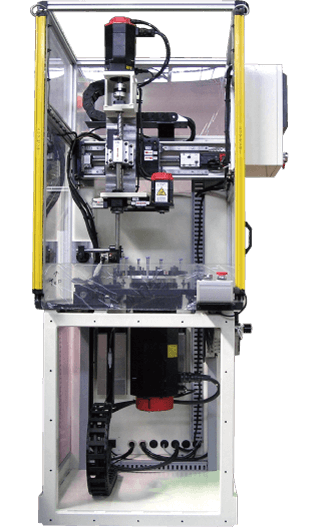

NC Inner Rotor Coil Winder

SW-38M-4

SW-38M-4 wind by controlled each axis with NC control device. While SW-38M-4 allow the copper wire to minimize the load, SW-38M-4 make the crossover process between electrodes and lead wire terminal process with the rotating mechanism. SW-38M-4 deal with Outer Rotor motor winding.

■Specifications

- Winding speed

- 300rpm(Max)

- Number of nozzles

- 1

- Nozzle stroke

- 40-200mm

- Winding direction

- reversible

- Wire size

- φ0.3-φ1.0mm

- Number of slots

- 6 or more

- Adaptive core bore

- φ40-φ100mm

- Adaptive core diameter

- φ95-φ160mm

- Adaptive core stack height

- 30-100mm

- Dimensions

- 1250W×1200L×2100H

- Weight

- 1200kg

- ※Winding speed depends on the specification.

- ※Adaptive stack height of core depends on the insulator.